Falmouth Harbour has begun boat trials on a unique eco-mooring system designed to protect sensitive areas of seabed from the scouring caused by traditional mooring chains.

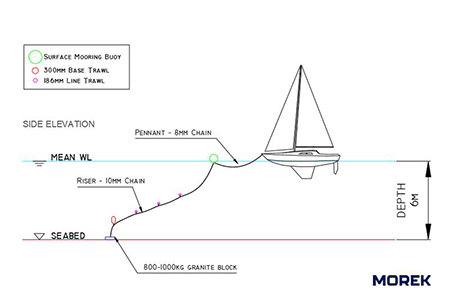

The Advanced Mooring System in place off Flushing Beach has been designed by naval architect & engineering firm MOREK, working with Falmouth Harbour’s marine operations team, with floats along the length of the mooring chain to lift it off the seabed.

Falmouth Harbour are now monitoring how a yacht attached to the AMS sits in the water – in all weathers and tides – to gauge how safe and practical the system is for wider use in a commercial and leisure harbour environment.

Environment Manager Vicki Spooner says, “We’ve put the trial AMS within one of the scour patches left by a traditional chain mooring – one of 11 removed by us in 2021 to allow the seagrass bed below to recover. More information is available here https://www.falmouthharbour.co.uk/environment/seagrass-regeneration/

“Ongoing monitoring of the scour patches by the University of Exeter shows the seagrass is regenerating itself which is fantastic – and if the AMS functions as well as we hope with a yacht attached, we potentially foresee using them in environmentally sensitive areas, or on the fringes of these areas.”

Falmouth Harbour, which sits within the Fal and Helford Special Area of Conservation, was successful in gaining £3000 backing for the trial in 2021 from the EU-funded TEVI (Cornish for “grow”) – a venture set up to create economic and environmental growth in Cornwall and the Isles of Scilly.

MOREK – a Falmouth-based marine engineering and naval architecture consultancy – have been collaborating with the harbour for the AMS project. MOREK have taken skills they more regularly apply to design and construction of marine renewable to provide the technical rigour required to develop the design of the new moorings. They have used Orcaflex software to model the likely performance of AMS within Cornish Harbours for TEVI and Natural England.

For this project MOREK’s engineers took the existing Stirling design and optimised it, focusing on reducing strain on the vessel’s cleats and its movement around the mooring. The result is an AMS that has minimal environmental impact while performing better than a block and chain equivalent. Now the project team is seeing for the first time how their “Stirling” design works with a yacht attached to the system.

MOREK Director Bob Colclough said: “The AMS design looks simple enough but the testing process is necessarily rigorous: to break through with new designs we need to provide extensive technical evidence of the performance, to ensure confidence to boat owners and insurers. It has been a real pleasure to be involved with this project, particularly to see our work contributing to the endeavours of Falmouth Harbour to pioneer a proactive approach to environmental sustainability.”

Falmouth Harbour CEO Miles Carden says, “We’ve been working closely with our harbour users throughout the stages of this trial – and seeing a boat finally moored on the AMS is an exciting moment.

“We need to learn more about how our eco-mooring performs in our particular waters as the use of AMS over areas where seagrass and maerl are found could be a significant way to reduce physical impacts from mooring and anchoring on the seabed below.”

Over the next two months Falmouth Harbour will be monitoring the boat’s movement around a central point and also cleat forces to increase understanding of the AMS and whether they can reliably be used in the future as a way of minimising impacts on sensitive seabeds.

For further information on the work of Falmouth Harbour and ongoing progress updates on its AMS trial visit https://www.falmouthharbour.co.uk/environment/advanced-mooring-systems-ams/